When a technical drawing of a part is done, in order to define its precision tolerances to the nominal dimensions and specifications should be added. To avoid designer having to specify every dimensions tolerances and help manufacturers easily asses the difficulty of manufacturing, the International Standard Organisation (ISO) published a general tolerance norm : the ISO2768.

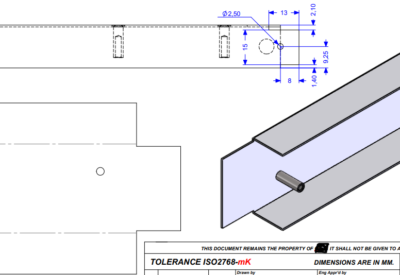

On a drawing mention of the norm name + two letters : for example ISO2768-mK or ISO2768-fH, will means that the intent of the designer was that all non otherwise specified tolerances on the drawing will have to respect below charts values.

ISO2768-1 general dimensional tolerances

The first part of the norm, refers to the general tolerances, which are the linear and angular dimensions without other tolerances on the specifications.

| Reference | Description | 0.5 to 3 | 3 to 6 | 6 to 30 | 30 to 120 | 120 to 400 | 400 to 1000 | 1000 to 2000 | 2000 to 4000 |

|---|---|---|---|---|---|---|---|---|---|

| f | Fine requirement | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 | – |

| m | Medium requirement | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 |

| c | Coarse requirement | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 | ±4 |

| v | Very coarse requirement | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 | ±8 |

| Reference | Description | 0.5 to 3 | 3 to 6 | More than 6 |

|---|---|---|---|---|

| f | Fine requirement | ±0.2 | ±0.5 | ±1 |

| m | Medium requirement | ±0.2 | ±0.5 | ±1 |

| c | Coarse requirement | ±0.4 | ±0.5 | ±2 |

| v | Very coarse requirement | ±0.4 | ±1 | ±2 |

| Reference | Description | Up to 10 | 10 to 50 | 50 to 120 | 120 to 400 | More than 400 |

|---|---|---|---|---|---|---|

| f | Fine requirement | ±1° | ±0°30’ | ±0°20’ | ±0°10’ | ±0°5’ |

| m | Medium requirement | ±1° | ±0°30’ | ±0°20’ | ±0°10’ | ±0°5’ |

| c | Coarse requirement | ±1°30’ | ±1° | ±0°30’ | ±0°15’ | ±0°10’ |

| v | Very coarse requirement | ±3° | ±2° | ±1° | ±0°30’ | ±0°20’ |

ISO2768-2 geometrical tolerances

The second part of the norm is about geometrical tolerances, like perpendicularity, flatness, straightness etc.

Please note that the general dimensions tolerances applies for roundness (through the diameter value) and parallelism.

| Reference | Up to 10 | 10 to 30 | 30 to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 |

|---|---|---|---|---|---|---|

| H | 0.02 | 0.06 | 0.1 | 0.2 | 0.3 | 0.4 |

| K | 0.5 | 0.1 | 0.2 | 0.4 | 0.6 | 0.8 |

| L | 0.1 | 0.2 | 0.4 | 0.8 | 1.2 | 1.6 |

| Reference | Up to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 |

|---|---|---|---|---|

| H | 0.2 | 0.3 | 0.4 | 0.5 |

| K | 0.4 | 0.6 | 0.8 | 1 |

| L | 0.6 | 1 | 1.5 | 2 |

| Reference | Up to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 |

|---|---|---|---|---|

| H | 0.5 | 0.5 | 0.5 | 0.5 |

| K | 0.6 | 0.6 | 0.8 | 1 |

| L | 0.6 | 1 | 1.5 | 2 |

ISO2768 usages

The tolerance ISO norm is very popular for metal sheet parts, precision machining parts and plastic injection parts designing. Casting parts usually use different tolerance norms for the raw casting parts.

Are the tightest tolerances always better ?

Parts designed with tightest tolerances will be closer to nominal values and therefore easier to integrate with other parts in mechanical assemblies. But tighter tolerances means more difficult parts to manufacture and therefore more expensive parts. In order to have effective design to cost approach, tolerance requesting should be matched with manufacturing means default capabilities.

Recommandations

Usage of the ISO2768 norm is very widespread and convenient, but you should not forget that too loose or too tight tolerancing on your drawings will impact the feasibility of your parts.

The version used of the norm used for this article is 1989, please be aware that new version may be published in the future.